My wife presented MASTER OF G – Air : GWR-B1000 1A1JF to me, which belongs to CACIO G-SHOCK Series, the lightest weight in the G-SHOCK GRAVITYMASTER lineup. Yes! I wanted such model which can support the shooting with my cameras. Appreciate very much. Thanks a lot!!

GRAVITYMASTER GWR-B1000 1A1JF

Surprised at the extremely right weight in spite of relatively larger body size and each larger bottom size. Another big surprise is the selected resin type for the tough body case.

Bezel with the beautiful weave pattern

Carbon Bezel. At first 52 multi layered carbon sheet is created. Then carve the shape of bezel. Finally the polishing process is applied. Yes, it’s quite intricate with meister mind and much effort. Then this metal replacement countermeasure must be a part of tough and light feature of GWR-B1000, realizing handsome aspect.

Carbon monocoque case

It’s quite robust and light weight solution with carbon fiber reinforced plastic solution. At first I thought it must be some thermoset resin with carbon fiber and impact modifier to realize more exact dimensional stability, since the precision controlled electrical parts are installed. But this my consideration was completely wrong. I found out the interview article of Mr.Iguchi, who is manager of exterior parts development section No.2 of Casio, in one of Web IT Magazine, IT Media news. In the article he told about the material.

Surprisingly it is carbon fiber reinforced PEEK (Poly Ether Ether Keton ) resin. It has been used for highly demanding parts in aero space industry and durable parts in powertrain segment’s unit in automotive world. Absolute and ultimate very best solution as semi-crystalline thermoplastic material for metal replacement. Almost all other plastics are not so easy to take over the performance of PEEK on the balance of tech demands among stiffness, strength, Impact strength (Shock Resistance), abrasion resistance, heat resistance, chemical resistance, creep resistance in higher temp. range, flame retardant performance (UL-V0) and dimensional stability with temp. change after confection processing. Yes, some of plastics are competitive on the specific material property against PEEK. But the considering the total balance among various material properties, I want to say PEEK must be the champion as thermoplastic material.

Material performance itself is very best. But the injection processing seems to be not so easy. In the web site material guideline, CAMPUS plastic datasheet, we can see the material data of VESTAKEEP® 2000 CF30 (PEEK-CF30wt%) produced by © Evonik Industries AG (Essen, Germany). The data sheet tell us that the melting temp. is 380 deg.C. When we look at the temp. of PPS ( Poly-Phenylene-Sulfide ), which is the popular with hot portable water valve applications and various automotive power module parts of EV, FCV and (P)HEV, it’s roughly 310 to 325deg.C. Therefore the melt temp. is quite higher level as semi-crystalline thermoplastic materials. On the other hand, the glass transition temp. (Tg) is not so higher, merely 148deg.C. So the data sheet set tool temperature for injection processing, at 180deg.C. Big gap between melt temp. and tool temp. Then roughly 30deg.C difference between Tg and tool temp. must be to avoid recrystallization annealing process with realistic and productive cooling time of injection processing. Typical situation is that actual injection workshop tend to apply relatively lower tool temp, closer into Tg, 170 or 160detg.C for example in case of PEEK. Such situation must lead the difficulty of dimensional stability control and instable mechanical properties. Referring into the data sheet, especially I feel high precision control requirement of injection pressure and hold on pressure, which has trade-off situation between injection profile’s surface finish and less flash for better surface finish. Then as one of possible case, carbon fiber in PEEK compound also provide more severe condition to realize good surface finish. Because the coefficient of linear thermal expansion between carbon fiber and thermoplastic material are not same. © GÖTTFERT Werkstoff-Prüfmaschinen GmbH, who provide various measurement and analysis test equipment for plastic and elastomeric materials, show us PVT (Pressure, Volume, Temperature) curve of PEEK in their own web site. In any pressure level in the graph, PEEK has inflection point at higher temp. range > 300deg.C. Therefore when put hold on pressure, paying attention into inflection point, CACIO’s injection workshop must avoid trade off situation as I described. Actually near side button, I can find out the parting line obviously. The resin thickness is different on the line. Then around the button, there is the relatively and slightly a little bit acceptable rough surface part on the profile surface. It must be the evidence that CACIO tackled with the severe trade off issue. Therefore if I must say the modification request to CACIO, I appreciate if they apply polishing treatment at the parting line portion to get more and more smooth surface. This additional process add the cost. Even in such case, if the price increase level is +50,000 to +100,000JPY level, I still pay for the added value of GWR-B1000 and Brand value of G-SHOCK GRAVITYMASTER. Actually I can’t understand why CACIO’s marketing dept. and sales dept. set the current price for GWR-B1000. They should be more confident on the value of product, long lasting endurance performance and the great G-Shock brand value.

I picked up the data of Evonik’s VESTAKEEP 2000 CF30 as the data of PEEK from CAMPUS plastic data. But please be aware of the fact that this is merely example to explain about the general feature of PEEK material. I’m quite not sure which commercial material of PEEK CACIO actually selected.

When I see some of the conventional G-SHOCK models, button guards are allocated. The guard aspect might initiate the shock resistant image. But it also must lead “usual” design image. I like “Non” button guard. Thanks to the elimination, quite remarkable large bottom aspect is more naked. Such different design aspect is quite nice. Then CACIO put titanium plate part on top of large size button. It must realize scratch & abrasion resistance on buttons, keeping lighter weight and rust resistance.

A large button is allocated at the 6 o’clock position. Can turn on the LED light to confirm the movement. When I enjoy the photo shooting during cold winter season, I wear gloves. Large size button is quite welcome for the easy operation.

I’ve used the resin band model of G-SHOCK, GS-1000J for more than 10 years. Normally the cheap polyurethane band start to show the tackiness on the surface due to hydrolysis problem during long time usage. But my GS-1000J still never show such tackiness problem even after over 10 years usage. Therefore I have quite good image on the plastic band quality of G-SHOCK. Polyurethane resin has wide variety. According to the selection of monomers for the polymerization, isocyanate, polyol and chain extender, the material properties are changing a lot. CACIO must select some high performance polyurethane polymer structure for longer endurance.

Anyway according to the experience from the usage of G-SHOCK, I don’t mind the usage of the plastic band for GWR-B1000 1A1JF. The band adopted TORAYCA of TORAY. I can see the marking on the band, PUR-CF10%. So the material include carbon fiber 10wt%. Then the base resin must be TPU ( Thermoplastic polyurethane). I start the long time usage of GWR-B1000. And confirm the durability of the resin band too.

By way of Bluetooth connection, Smartphone app, “G-SHOCK Connected”, is possible to connect with G-SHOCK Watch. If the model has the function of Bluetooth connection, any model can link into G-SHOCK Connected.

- Automatic time adjustment ( 4 times a day)

- Set up WORLD TIME (Select globally from over 300 cities )

- Dual analogue displays (HOME TIME / WORLD TIME)

- Alerm / Timer

- Smartphone Search

At first, pairing between your G-SHOCK and the App should be done like as other Bluetooth connection app.

- Install “G-SHOCK Connected” at Google Play or App Store. In this instruction, it’s iPhone.

- Set up your Smart Phone to use Bluetooth connection.

- On the smartphone display, tap the icon of G-SHOCK Connected.

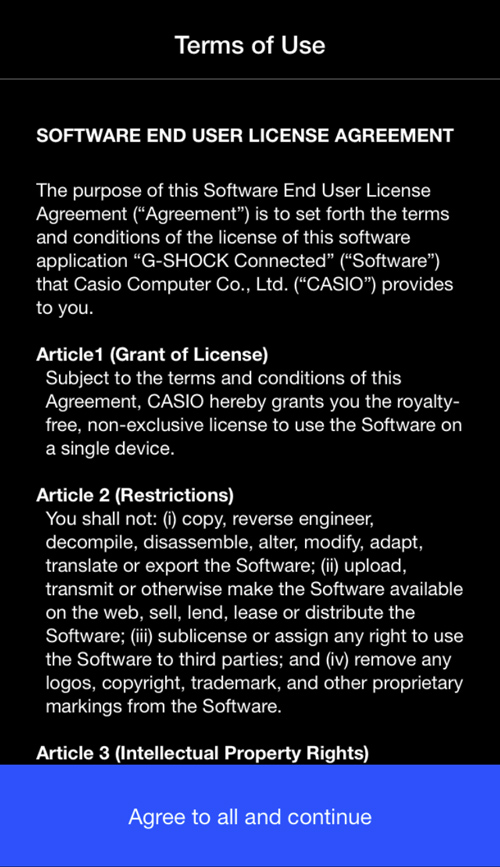

- After tapping, the logo of G-SHOCK appear. Then Term of Use is introduced.

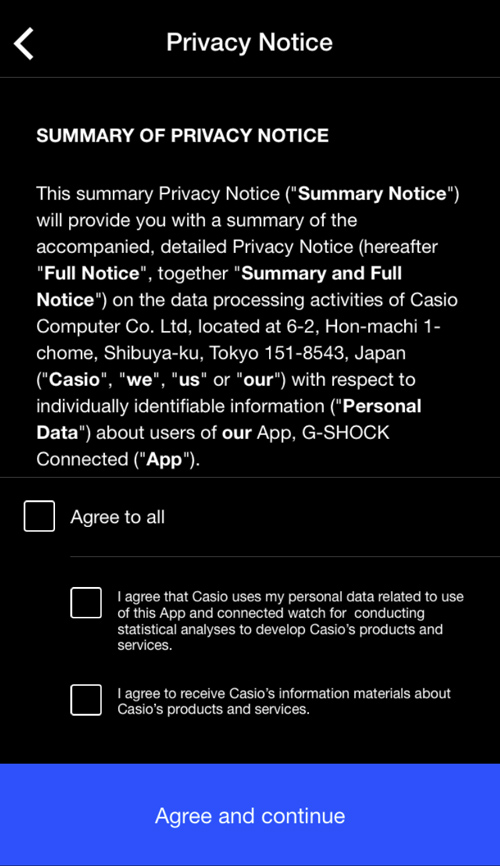

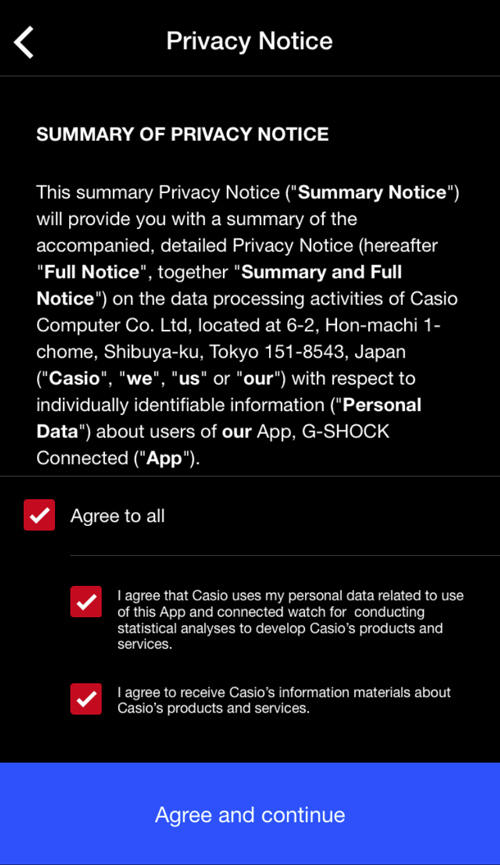

- Privacy Notice. If you agree, put 3 check marks.

Put marks if you agree.

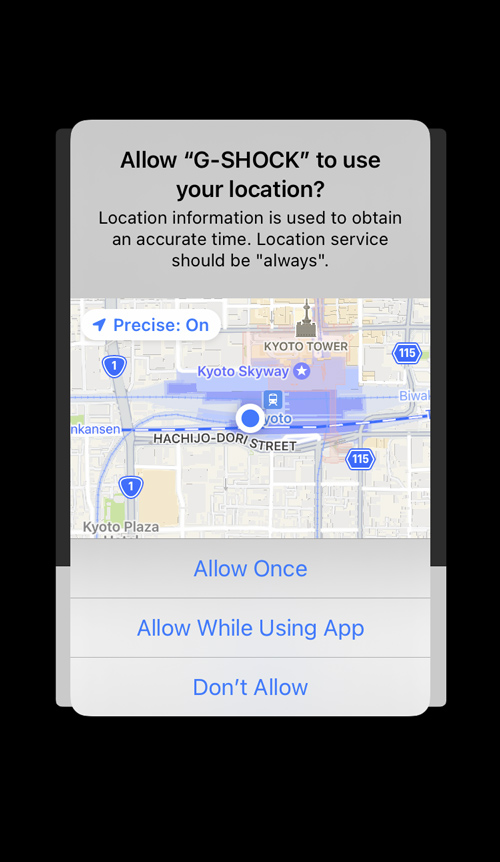

- Select from 3 options on the usage of your current location. If you would like to use Flight Log function, select the service, “Always”. The selection is possible, if you go to iPhone’s ( or Android’s ) basic setting menu.

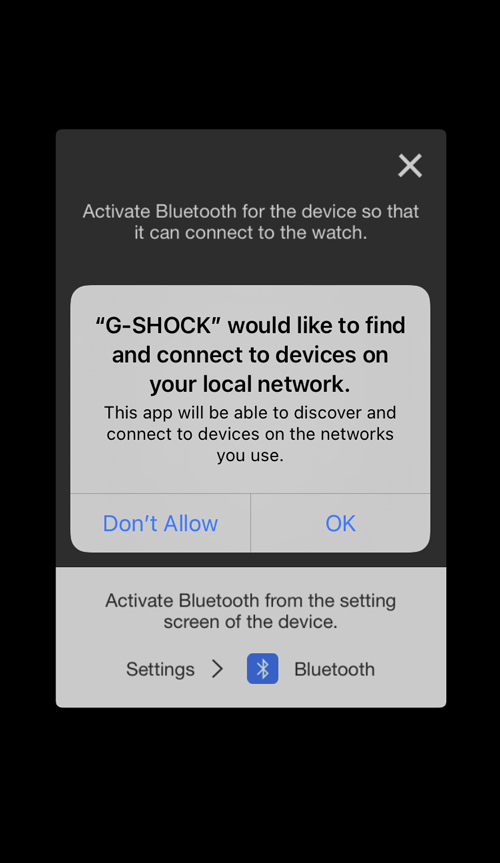

- If you agree G-SHOCK connect your local network, tap “OK”.

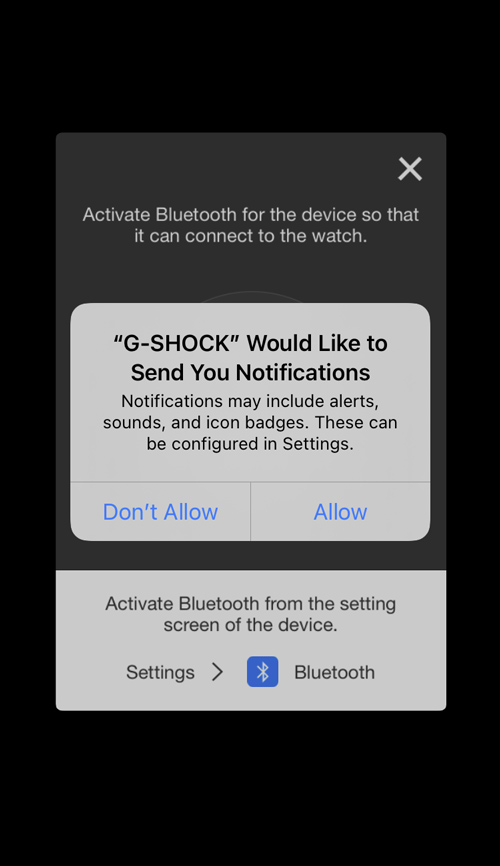

- The notification delivery. Depend on your choice.

Up to you.

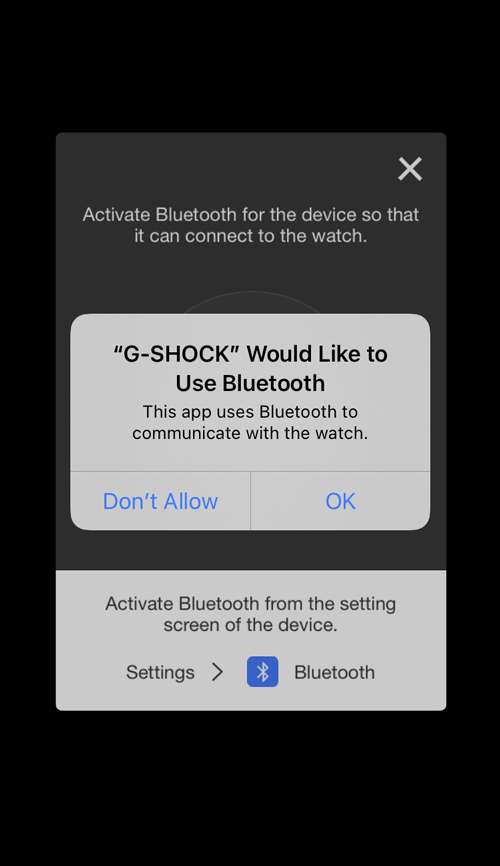

- Tap “OK” Otherwise impossible to connect with your G-SHOCK.

Tap “OK”

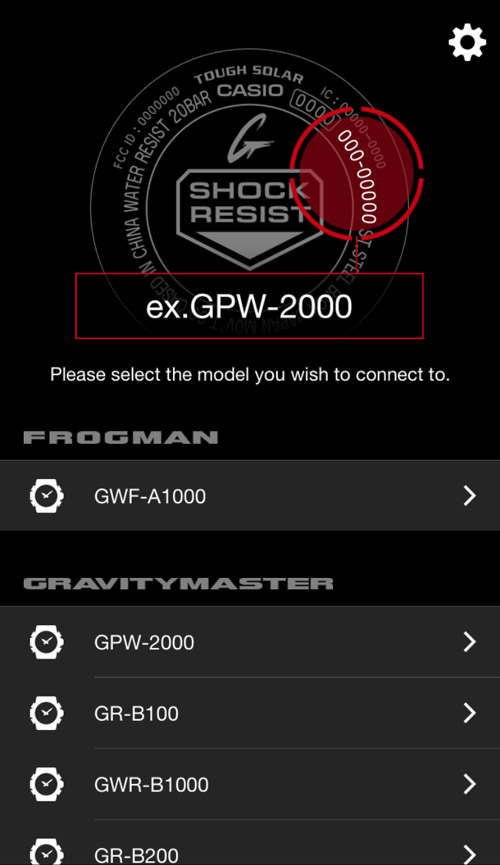

- The list of G-SHOCK model appear. In my case, select GWR-B1000.

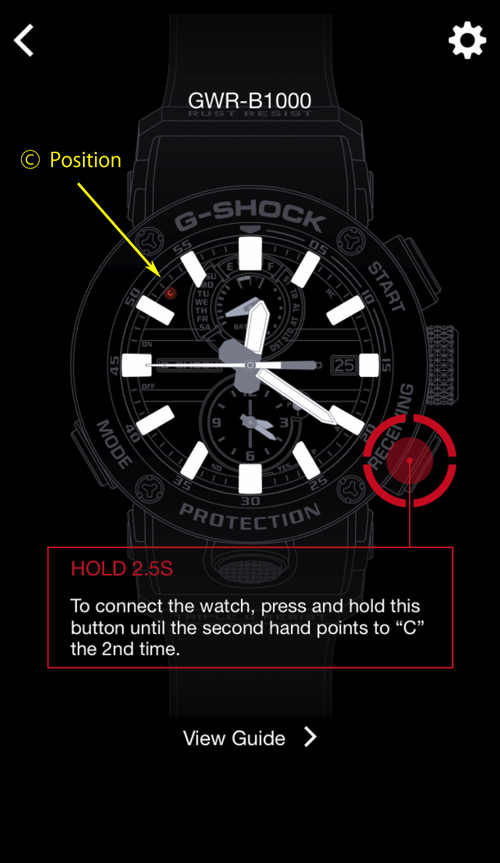

- Press the button under crown (winding knob) and hold 2.5 seconds until second hand meet at Position; Ⓒ. Before reach 2.5 seconds, once you can hear one shot signal. Your figer shouldn’t leave from the button at the signal. Otherwise, we must press and hold 2.5s again. When the second hand reach Position Ⓒ, finally you catch the double shots signal. Then can leave fro button.

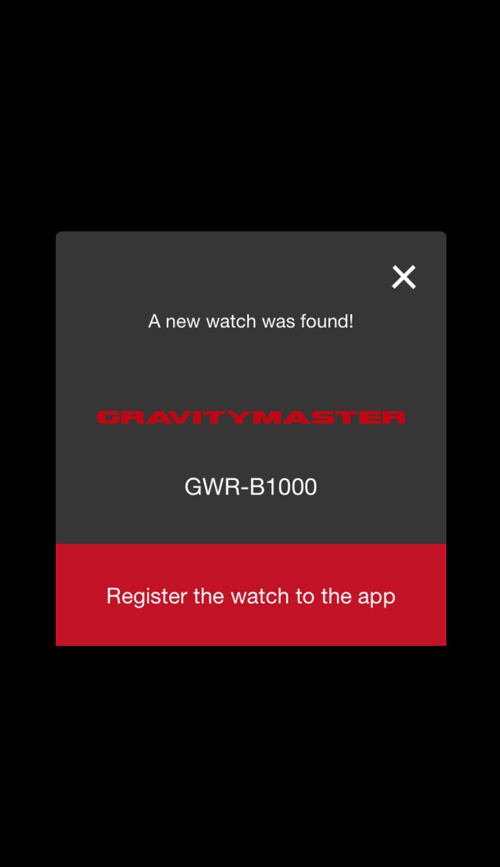

- Your smartphone found out your G-SHOCK. Tap “register the watch to app”

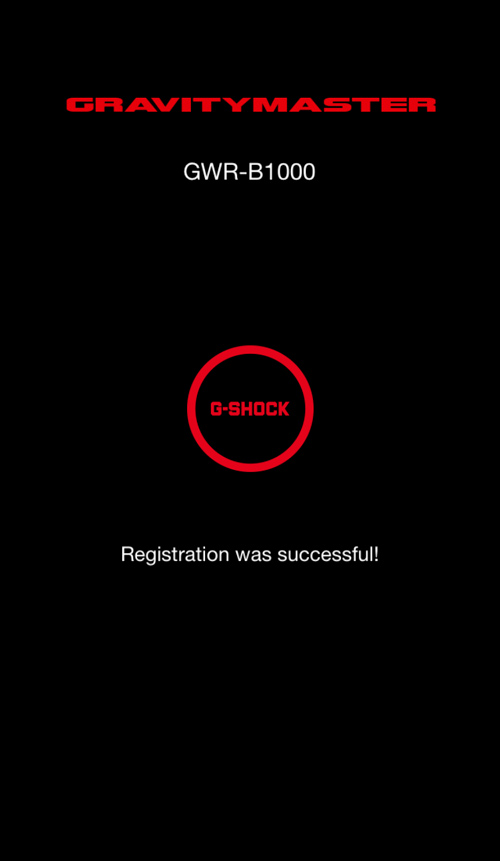

- Registration finshed. Paring process was completed.

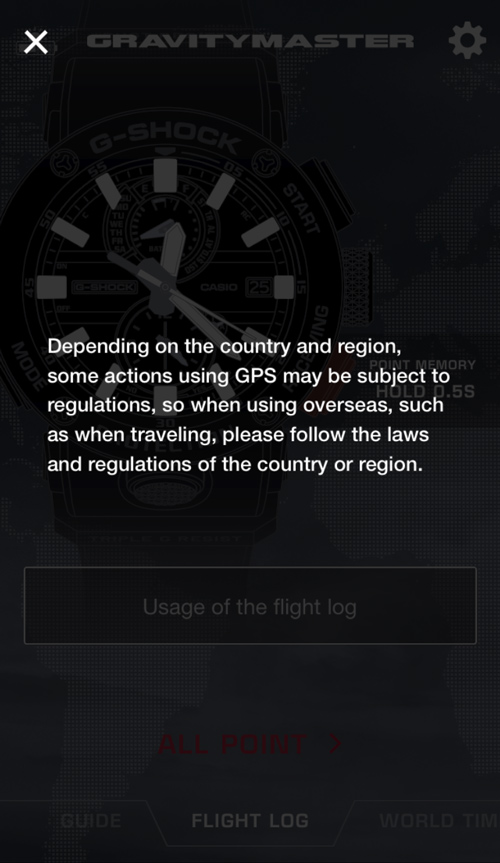

- Attention of GPS usage appear after the registration.

- Press the button under crown and hold 2.5s again to connect your watch into “G-SHOCK Connected”.

- In case of GWR-B1000, there are follow menu;

- GUIDE

- FLIGHT LOG

- WORLD TIME

- UTILITY

After the usage of each menu, I felt WORLD TIME (Dural Time ) function is the most useful. So at first, explain about this function.

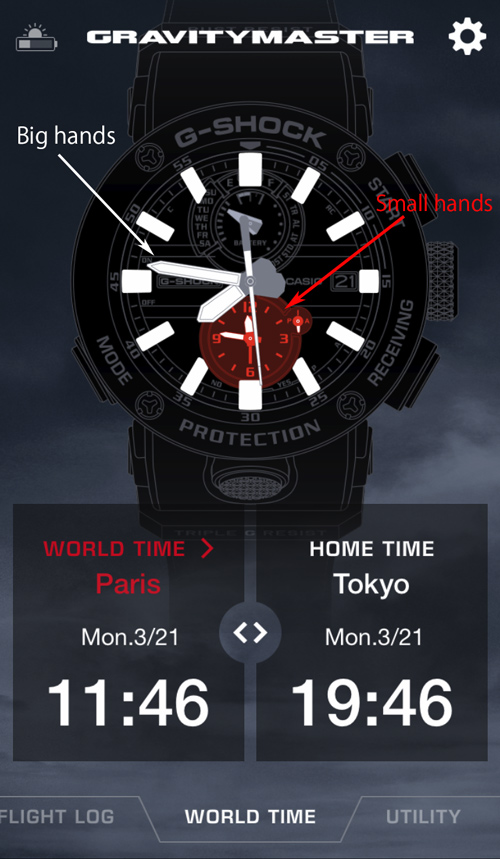

WORLD TIME = Dual time function. The main big hands show the time at your present location. The small hands at 6 o’clock position shows the time of your travel destination or time zone of your optional contact location.

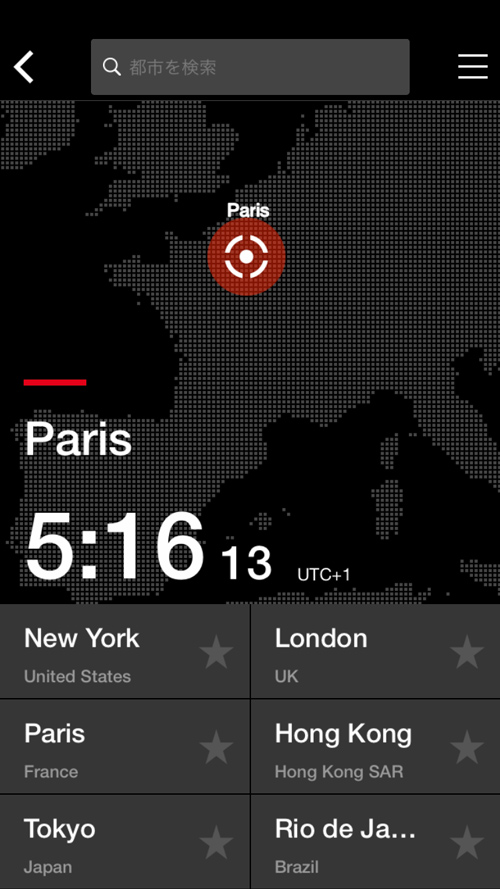

- Tap red font part, “WORLD TIME >” to reach the page to select your target time zone as WORLD TIME.

- Select city as time zone for WORLD TIME.

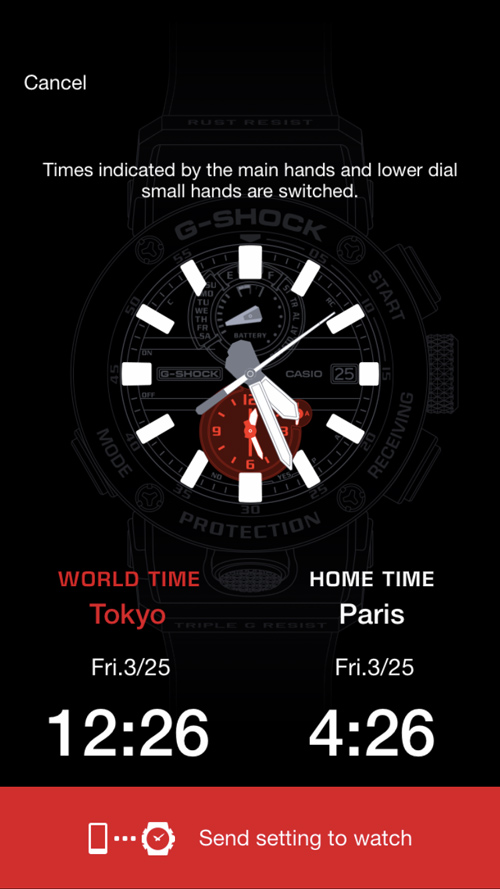

- Tap the mark, < >, to start the process of time exchange

- ↓On the display of your smartphone, WOLD TIME and HOME TIME are exchanged already. But in actual G-SHOCK watch, it doesn’t change yet. To start the replacement seriously, tap “Send setting to watch”

In case of traditional G-SHOCK models, which doesn’t have Bluetooth connection function, the selection of time zone is pretty complicated. For example, I’ve used G-SHOCK GS-1000J. This model has various logo of city name around watch face near border of bezel. Then step by step, I must press small side button to meet the second hand the target time zone city. Even GWR-B1000 has same function. But this watch doesn’t have the logo of city around watch face. Therefore to know the target position of second hand for time zone selection, we must look at the time zone list in instruction document of Module No.5588.

Looking at the complicated process, dual time adjustment on smartphone display with “G-SHOCK Connected” is quite convenient.

- If you would like the time exchange again to recover the original set up, start to repeat the process to tap the mark, < >.

- There is another way to recover the original dual time setting. Cut Bluetooth connection. Then press the button above crown and hold 3 seconds. After 3 seconds, the big hands and small hands start the rotation to recover the original dual time setting.

Add the explanation of other functions later.

To cancel the connection, just press the button under crown shortly.

MINOCAME

MINOCAME